Let us be your design and development department

We carefully develop and design the production tools you need to help you lean production at the lowest cost.

Our strict control and on-time delivery will leave a good impression on your customers. We don’t just design stamping tools. Industrial design, mechanical design are also part of our business. We understand you and your business, basically become your R&D design department.

We create unique designs for special needs.

We firmly believe in doing the best for our customers. We fine-tune the lean requirements you need – we listen to our customers and our designs are custom made to fit your company. Check out our success stories below.

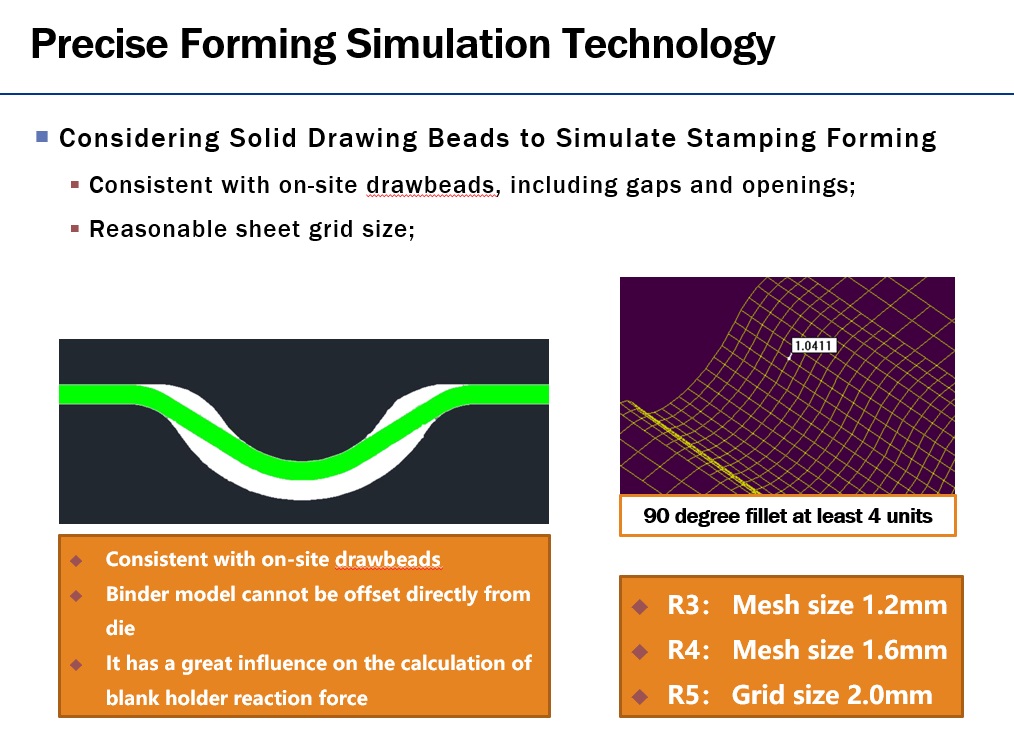

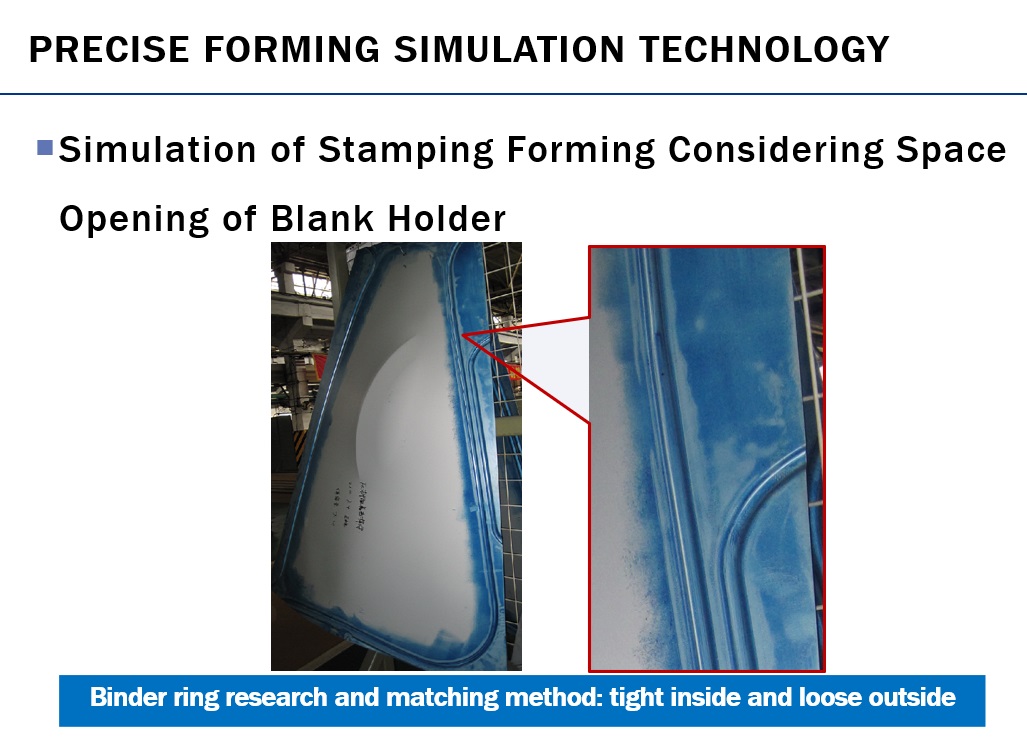

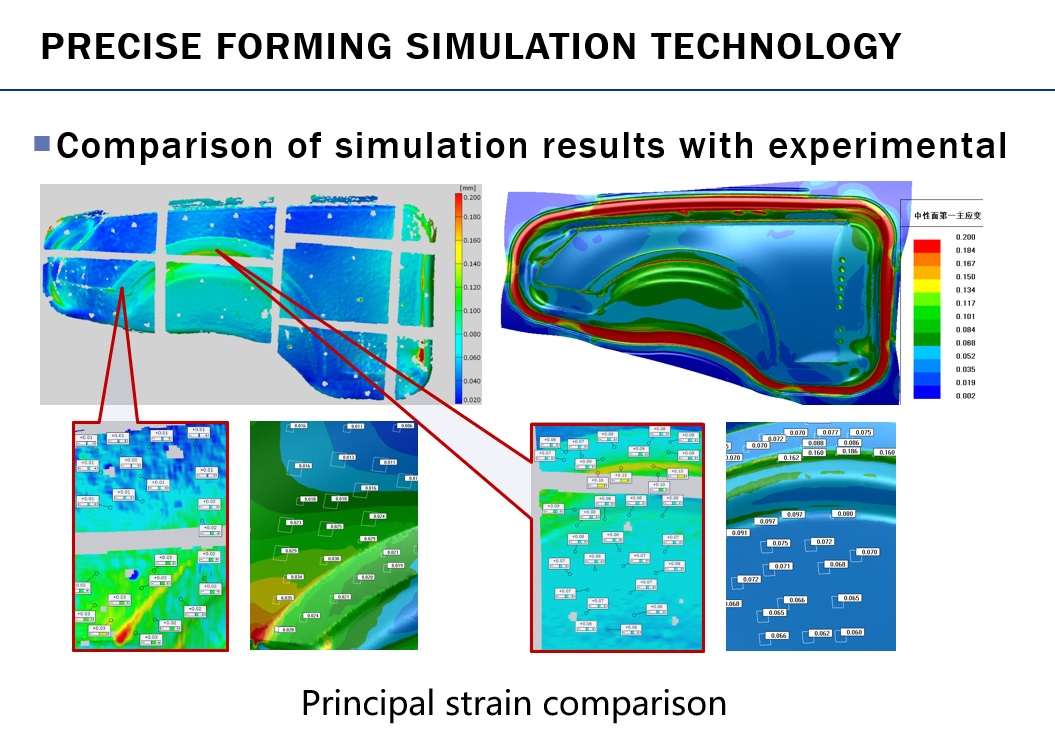

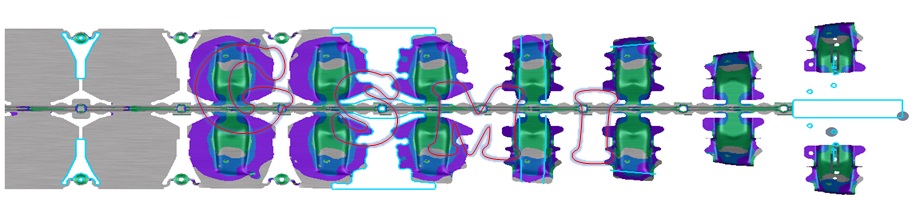

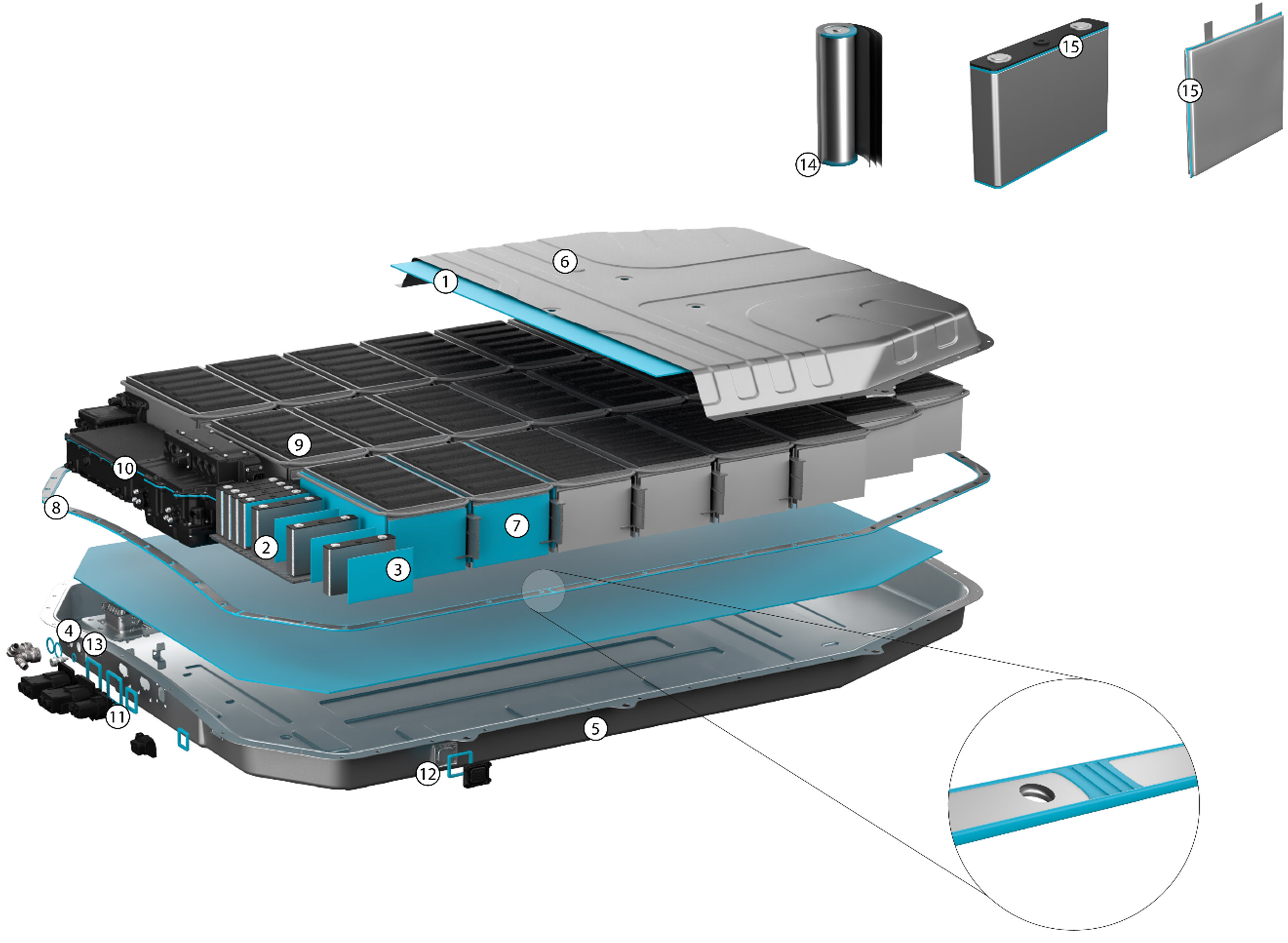

Pre-synchronous engineering/stamping SE for macro feasibility analysis allows analysis of product manufacturability and reduces the time and labor for tool design and manufacturing activities to an optimal level before starting tool design. In this process, analysis software is used to guide accurate, lowest cost and fast mold manufacturing by performing simulations in a virtual environment. All studies are presented to our customers.Process Stages

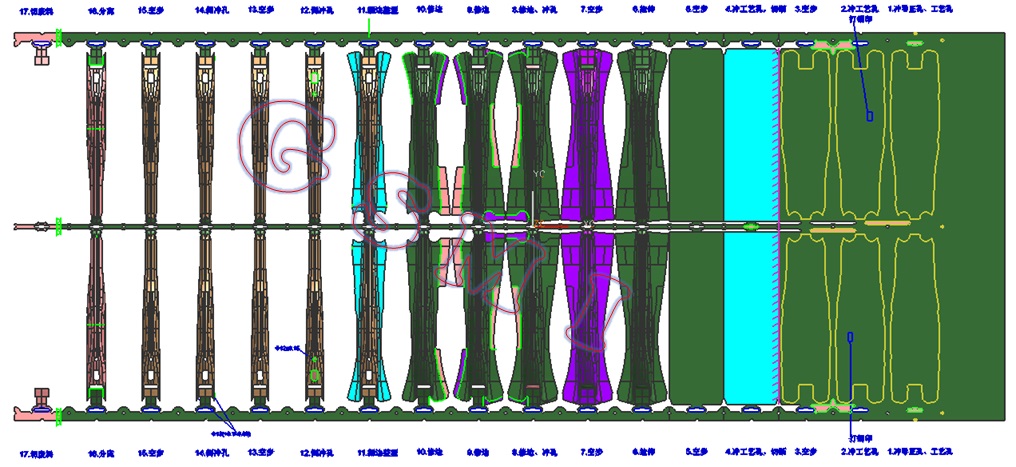

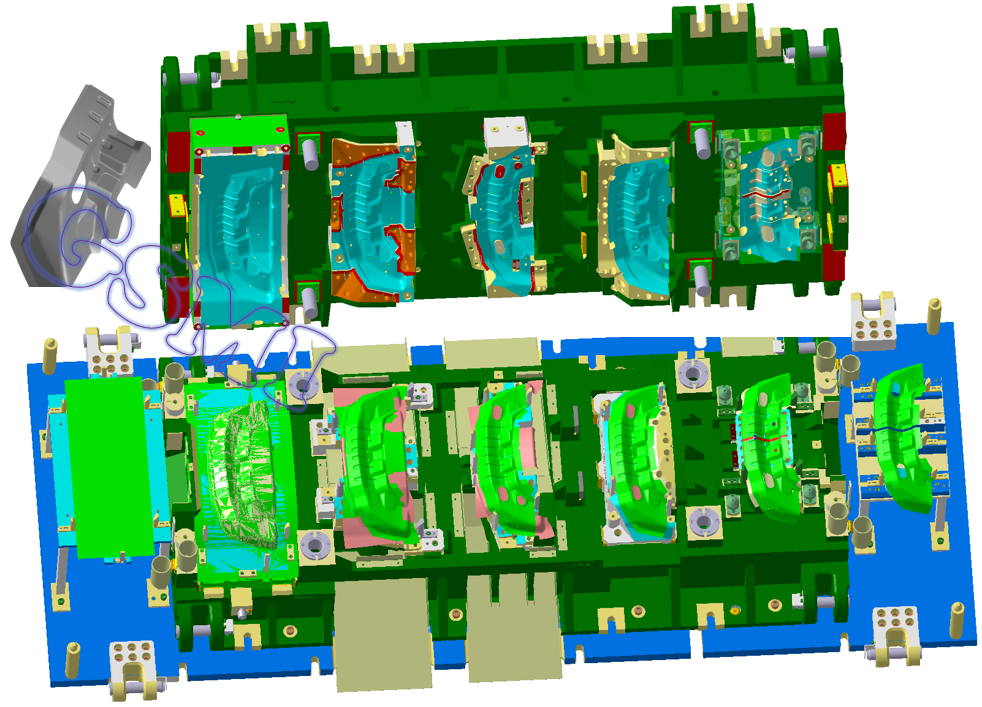

Continuous die stamping process design, automatic line stamping process design, and single process stamping process design using CATIA/UG.

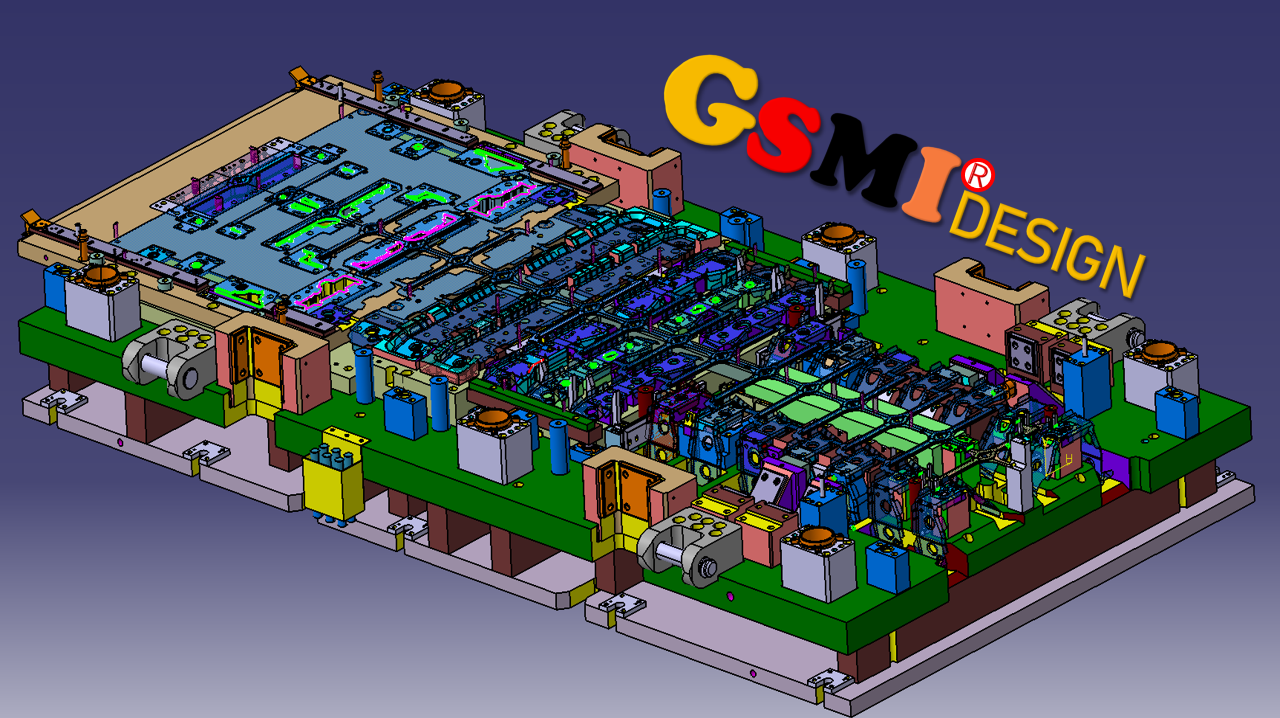

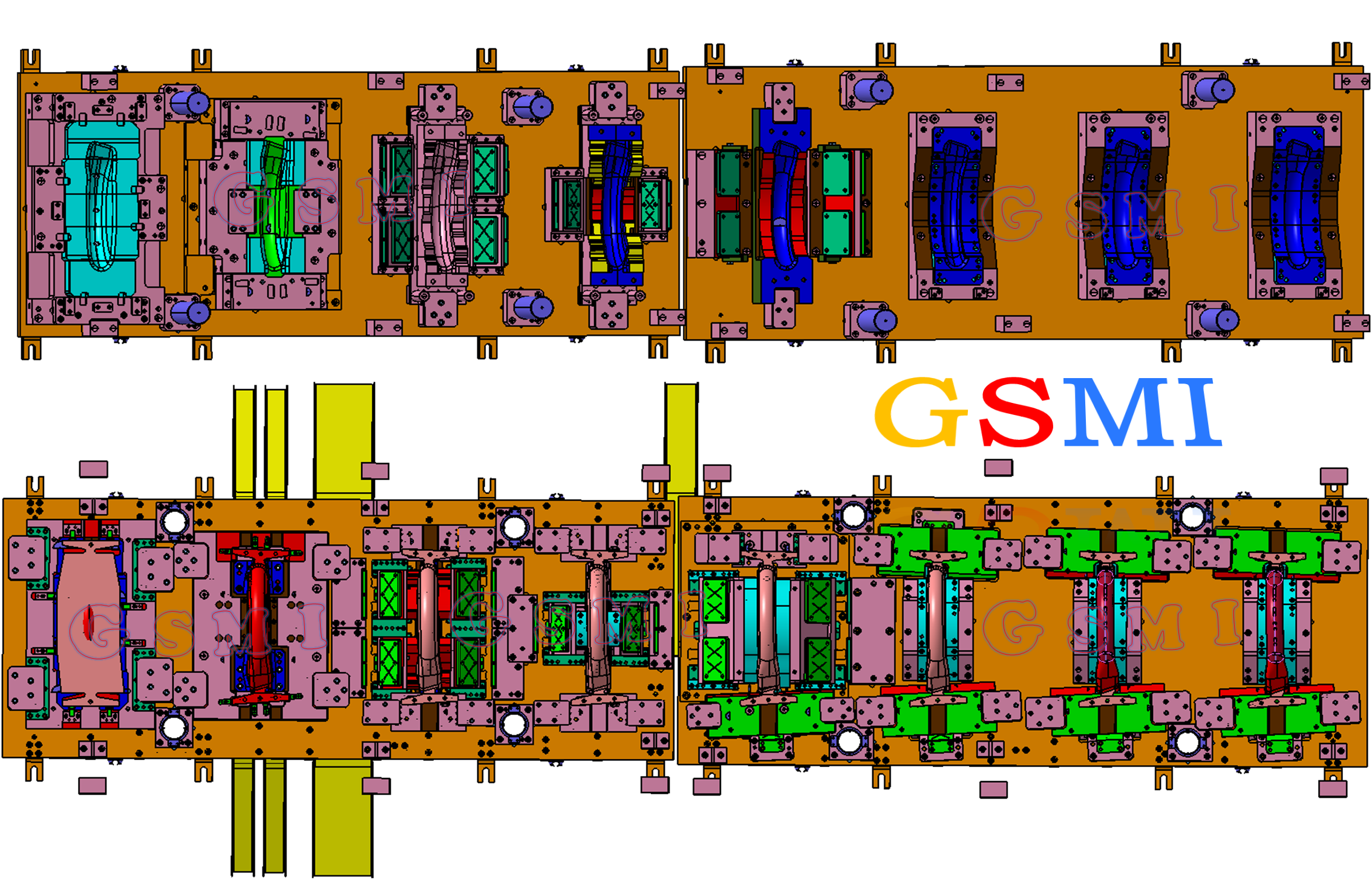

Single process mold design for steel plate and casting, continuous mold design for steel plate and casting, and automatic line mold design for steel plate and casting using CATIA/UG.

Stamping progressive die design

Transfer Die Design

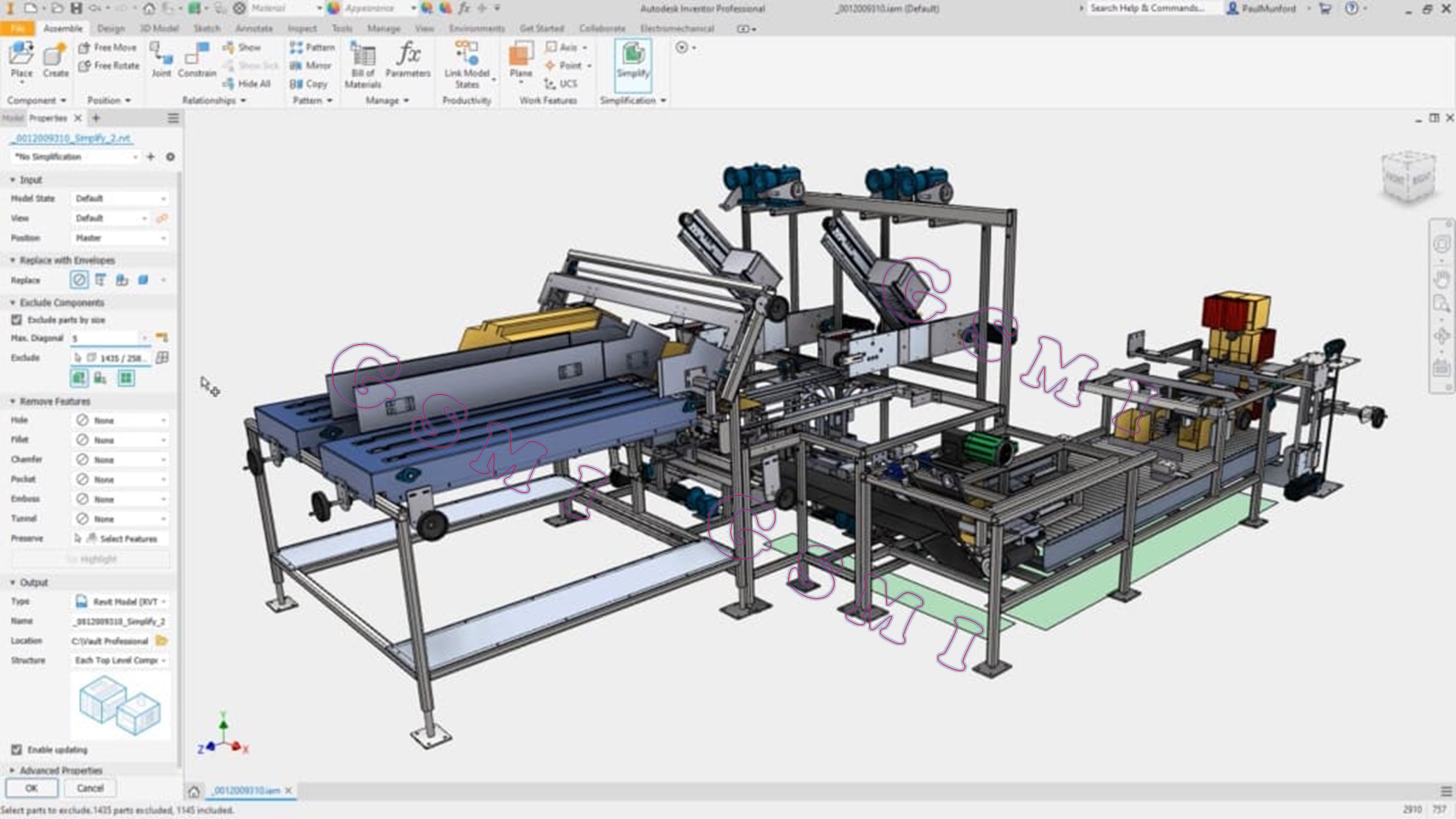

We use CATIA/UG/SolidWorks to design stamping lines and fixtures for the automotive industry, as well as automated machinery and equipment for the furniture, home appliance, aerospace, military, medical and health industries.

Using all of our engineering experience and infrastructure, we create functional, practical and aesthetic product designs that will meet our customers’ expectations at the highest level. We serve customers in all industries, with a special focus on automotive, white goods, defense and aerospace, and hygiene.

Why choose us

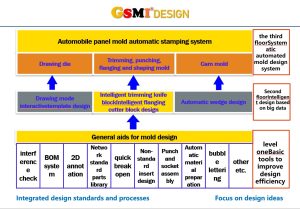

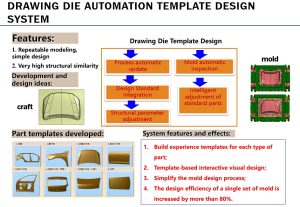

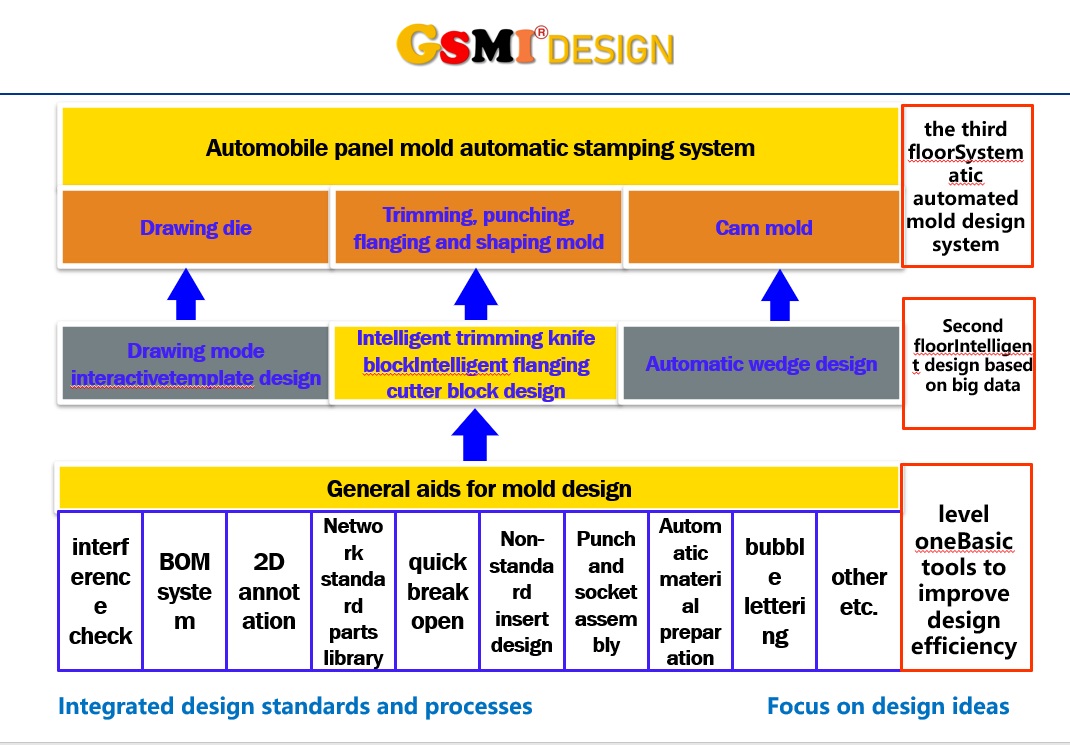

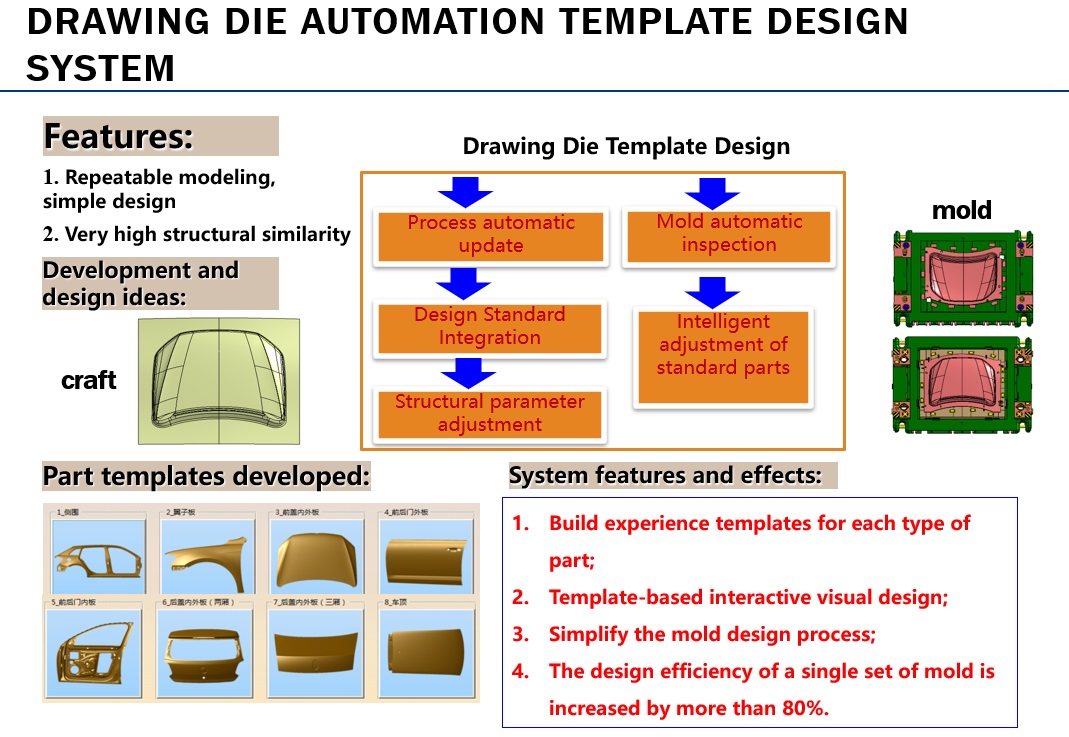

In the design department, we have a mold design group / fixture and automation design group. to meet the needs of our different customers. Our structural designers use NX, Catia, SolidWorks, CAD design software. Our process designers use, Autoform, dynaform, Jstamp, Pamstamp analysis software. A team of designers created in-house mold models to integrate customer feedback and lessons learned for progressive molds, transfer molds, and line molds.

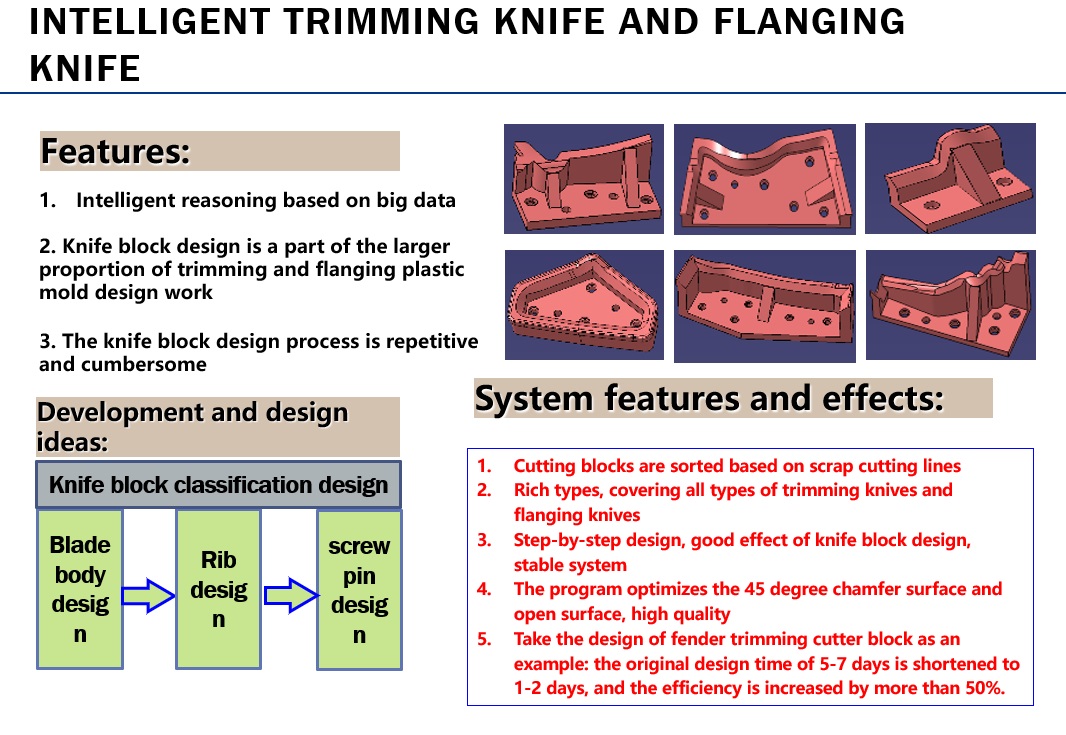

To improve efficiency, we also developed engineering design plug-ins to increase productivity. Created our own structural library to maximize efficiency. To ensure proper manufacturing release, we implemented continuous design review and inspection

The automation group works in conjunction with the tooling design group, allowing us to develop more economical production tools.

Our design department operates independently, in addition to working with on-site tooling manufacturing. Helping the industry develop designs for more efficient production tooling

We are served since 20 years to our customer with trust and we are happy

2000+

Projects Completed

200+

Happy Customers

20+

Years In Service

Service Company